In the fashion industry, reducing production costs is a priority, but achieving this without compromising quality can be a challenge. Labels, though they might seem a minor detail, have a significant impact on overall costs. However, as with other aspects of textile production, simply focusing on cutting expenses isn’t enough. It’s essential to find the right balance between profitability, quality, sustainability, and efficiency. Below, we examine some practical strategies to optimise the cost of clothing labels without sacrificing these key criteria.

Optimising materials: Savings without quality loss

Selecting cost-effective materials

Material choice is a critical factor in production costs. Choosing materials that are economically accessible and, at the same time, maintain an adequate quality level is possible. For example, using recycled polyester or blends of natural fibers can be a cost-effective option that also adds value in terms of sustainability. The key lies in selecting materials that offer durability and meet brand standards without incurring unnecessary expenses.

Reusing and recycling materials

Another way to optimise costs is through recycling or using reused materials. This approach not only reduces spending on new raw materials but also reinforces the brand’s commitment to sustainability, something increasingly valued by consumers. Quality need not be compromised if high standards of control are maintained when selecting recycled materials.

Enhancing production process efficiency

Implementing advanced technology

Technology plays a fundamental role in reducing costs. If your clothing label supplier has more efficient machinery or automates certain processes, production times—and hence operational costs—can be significantly reduced. Automated labelling machines, for instance, not only speed up the process but also reduce the chances of errors and material wastage, directly contributing to savings.

Purchasing strategies

Bulk purchases and long-term contracts

Bulk purchases often offer more attractive discounts, but it’s important to ensure that the purchased volume does not exceed actual production needs. Furthermore, signing long-term contracts with reliable suppliers guarantees price stability and a consistent material supply, avoiding sudden cost increases.

Alternative labels: Balancing quality and cost

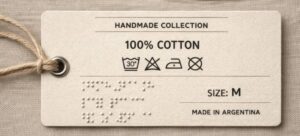

Evaluating lower-cost labels and their impact on brand perception

Reducing costs by using cheaper labels is possible, but it’s essential to consider how these decisions affect brand perception. Labels are an extension of brand identity and play an important role in the customer experience. It’s crucial that any cost reduction does not affect perceived quality, as this could negatively impact the brand’s reputation in the long term.

Sustainability considerations and their long-term impact on costs

Sustainability should not be viewed as merely a trend but as an investment in the future. While eco-friendly materials may have a higher initial cost, they can yield significant benefits over time in terms of brand reputation and access to new markets. Additionally, many consumers are willing to pay a bit more for products that respect the environment, making sustainability a competitive advantage.

Reducing clothing label costs requires a strategic approach. Our aim is to help clients find the right balance among all these factors so that cost reduction doesn’t impact the overall value proposition. In the end, small adjustments can yield substantial results, and the most important aspect is that the brand continues to offer a product that reflects its values and commitment to quality.