In the professional textile sector, every garment must do more than just serve an aesthetic or functional purpose — it often has to withstand extremely demanding conditions. This is especially true for clothing that goes through industrial laundering, such as in healthcare, hospitality, manufacturing, or textile rental services.

And there’s one detail that’s often overlooked but absolutely essential: the label.

There’s no point in investing in technical fabrics or reinforced stitching if the label fades, peels off, or becomes unreadable after just a few washes. That’s why, in this article, we’ll show you how to ensure your labels remain durable — even under the toughest conditions.

1. Choosing the right material: the foundation of a durable label

It all starts with the base. The material used for the label is key to ensuring it can withstand friction, harsh chemicals, moisture, heat, and repeated washing and drying cycles.

Industrial laundry processes involve conditions that are far more demanding than domestic washing: temperatures that can exceed 75 °C, highly alkaline detergents, bleaching agents like chlorine or peroxides, and more intense mechanical action. That’s why standard label materials often fall short.

At Indet, we use technical materials specifically engineered for these conditions, such as:

- Satin polyester: offers a sleek, elegant finish, is soft to the touch, and maintains excellent dimensional stability.

- Polyamide (nylon): highly resistant to wear and compatible with high-precision thermal printing.

- Tyvek or non-woven synthetic materials: ideal for industrial or healthcare environments where maximum chemical resistance is required.

The right choice depends on the type of garment, the industry it’s used in, and the kind of information the label needs to display. And most importantly, it must hold up after 50, 100, or even 200 industrial wash cycles.

2. Inks and printing: what you don’t see can make all the difference

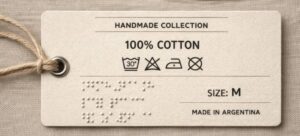

A durable label base won’t matter much if the print itself doesn’t hold up over time. In many cases, the label doesn’t fail by tearing — it fails when the information (such as fabric composition, care instructions, or traceability codes) fades, smudges, or becomes illegible.

That’s why printing technology plays a crucial role:

- Thermal transfer with resin ribbon: one of the most resistant options, especially against industrial washing and abrasion. Ideal for care labels and traceability information.

- Digital printing with industrial-grade inks: offers excellent versatility and customization. When using properly formulated inks, it also provides strong wash resistance.

- Thermo-embossing: in certain cases, such as size tags or fixed numbering, direct embossing can be used — a no-ink method that ensures permanent legibility.

At Indet, we recommend using certified inks and tested formulations specifically developed for industrial environments, ensuring that all label information remains clear and compliant throughout the garment’s entire lifecycle.

3. Attachment methods: making sure the label stays put

It’s not just about how durable the label is — how it’s applied to the garment matters just as much. The attachment method determines whether the label will survive dozens of wash cycles or end up loose in the washing machine after just a few.

Here are the main options we consider:

- Traditional stitching: still the most reliable and long-lasting method, especially for workwear or healthcare garments. When properly applied, it prevents the label from detaching due to heat, water, or friction.

- Heat sealing: applied with heat and pressure, this is ideal for technical garments or synthetic fabrics where stitching isn’t feasible. It requires compatibility between the label and garment materials.

- Technical adhesive: suitable for temporary labeling, logistics tracking, or internal identification. However, it’s not recommended for garments that go through laundry processes.

In each case, we assess the fabric, the purpose of the garment, and the type of washing it will undergo to determine the best attachment method.

4. Durability testing: it’s not enough to promise — you have to prove it

Theory is great, but at Indet, we go further. We understand that every industrial setting has its own specific challenges, which is why we carry out real-world durability tests before launching or recommending any label for intensive use.

These tests may include:

- High-temperature washes (up to 90 °C)

- Exposure to chlorine, alkaline detergents, or disinfectants

- Industrial drying (tumble or tunnel drying)

- Rubbing, ironing, and steam exposure

- Repeated cycles to simulate the full lifespan of the garment

Only when a label passes these tests — maintaining its integrity, legibility, and adhesion — do we consider it suitable for industrial environments.

This not only ensures compliance with standards like ISO 15797 or ISO 6330, but also gives our clients peace of mind, knowing the label will stay in place and readable to the very end.

5. Customization, traceability, and compliance: functionality without compromising durability

Today, labels do much more than just provide aesthetic or basic product information — they’ve become essential tools for control, traceability, and regulatory compliance.

In industries like healthcare or textile rental, it’s common for labels to include:

- QR codes or barcodes

- Unique identifiers per garment or batch

- Production and origin details

- Multilingual care instructions

- Compliance with standards like REACH, OEKO-TEX®, and others

The key is ensuring all of this is printed on a material — using the right technology — that guarantees clear readability even after dozens of industrial wash cycles. A traceability code is useless if it can’t be scanned after just a few weeks of use.

At the end of the day, the label is part of the garment’s quality. It reflects the brand’s attention to detail, commitment, and standards. At Indet, we’ve been developing labels that last as long as the garments they’re attached to for over three decades — because if a garment is made to endure, the label should be too.