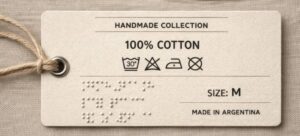

We’ve mentioned before that labels are not just there to provide information about garment care or materials – they also play a vital role in communicating brand identity and values. But in industries such as sportswear, outdoor apparel, swimwear, or workwear, labels have to go even further: they must withstand extreme conditions without losing their integrity or readability.

Take, for instance, an inner label that becomes illegible after just three washes, or a decorative label that starts to peel off after the first wear. Or consider more demanding settings: industrial uniforms subjected to high-temperature washing processes, or children’s clothing that survives everything – except the label. These seemingly small details can have a significant impact on both brand image and the customer’s overall experience.

At Indet, we’ve spent years working alongside leading brands to tackle these challenges. But what exactly needs to be considered when designing labels that can withstand water, harsh washing cycles, daily wear and tear, and – increasingly – sustainability requirements?

What does “resistant to extreme conditions” really mean?

It’s not enough to say a label is “durable” – it’s essential to define the type of resistance required, depending on how the garment will be used. These are some of the most common scenarios we need to plan for:

- Frequent industrial or domestic washing at high temperatures or with aggressive detergents.

- Prolonged exposure to moisture or water – as in swimwear, sportswear, or nautical gear.

- Changing weather conditions (intense sun, extreme cold, rain…), particularly in outdoor clothing.

- Contact with chemicals such as disinfectants, chlorine, or even cosmetics.

- Constant friction from wear or rubbing against skin, backpacks, belts, or tools – typical in workwear or military garments.

- Sweat and body heat, which can degrade low-quality materials.

Designing labels with these challenges in mind doesn’t just extend their lifespan – it also reduces returns, enhances product perception, and prevents customers from cutting out or removing the label, which is more common than you might think.

Technical materials: Choosing the right one is the first step

The durability of a label starts with its composition. Not all fabrics or finishes are created equal, and making the right choice can be the difference between a label that lasts for years – or just a few weeks.

1. Satin or heat-sealed polyester

One of the most versatile materials available. Its smooth surface allows for sharp printing, it’s soft to the touch, and it doesn’t fray. It can be sewn on or applied using heat, and offers good resistance to water and washing. Ideal for inner care or composition labels.

2. Tyvek®

A non-woven material made from high-density polyethylene fibres. Tear-resistant, water-resistant, mould-resistant, and highly abrasion-resistant. Its technical look makes it a popular choice for outdoor clothing, footwear, or garments with a functional aesthetic. Excellent for hangtags or integrated labels that need to withstand moisture and the elements.

3. TPU (Thermoplastic Polyurethane)

This flexible, translucent material allows for a clean, modern design. It adheres easily with heat, is waterproof, tensile-resistant, and highly durable – even after numerous wash cycles. Commonly used for decorative labels on high-performance garments.

4. Technical rubber, silicone, and phthalate-free PVC

Ideal for external labels, logos, or 3D finishes. These materials add character to a garment while standing up to harsh weather conditions. With the right design, they also offer high levels of UV and mechanical wear resistance.

5. Special adhesives

For temporary labels (such as those used in textile packaging), there are adhesives that resist water or abrasion – though it’s always important to decide whether you want a removable or permanent option. We also develop self-adhesive labels suitable for wet or damp environments, such as swimwear or towels.

Design: Clarity, technical precision, and durability – without compromising on style

A durable label isn’t just about “holding up” – it must also be functional, comfortable for the wearer, and aligned with the brand’s visual identity. When designing labels for extreme conditions, a few key principles apply:

- Long-lasting, legible printing: Thermal transfer or laser printing is recommended, as it penetrates the material and offers better resistance than traditional screen or offset printing.

- Sealed stitching or heat application: A heat-sealed label not only integrates more smoothly into the garment, but also prevents chafing and detachment.

- Clean, purpose-driven design: Clear typography, well-structured information, durable symbols, and strong contrast all contribute to a more effective label.

- Strategic placement: A swimsuit label is not the same as one for a ski jacket. Avoiding high-friction areas increases the label’s longevity and wearer comfort.

- Technical finishes: Depending on the context, labels can be made non-slip, flame-resistant, antibacterial, or printed with reactive inks.

In short: a well-designed label should live in harmony with the garment – not be a nuisance or a point of weakness.

Sustainability: Can a technical label also be eco-friendly?

The answer is yes. At Indet, we believe that sustainability and durability should go hand in hand. Here are a few key points:

- Use of recycled materials, such as PET polyester made from plastic bottles.

- Water-based or solvent-free inks, which reduce the chemical footprint.

- Waste reduction in production, thanks to laser cutting or seamless heat-sealing techniques.

- Certifications such as OEKO-TEX® or GRS, which guarantee materials are safe for both skin and environment.

- Minimalist, multifunctional designs that avoid redundant labels and reduce material usage.

What’s more, a label that lasts the entire lifetime of the garment is, by definition, more sustainable – it avoids the need for replacements, returns, or later modifications.

More and more brands are embracing collections that are technical, versatile, and built to last. And on that journey, the label must not be left behind. A well-designed, durable labelling solution enhances not only the perceived quality of the garment but also its overall coherence and functionality.

At Indet, we create labels that go far beyond just providing information: they accompany, endure, communicate, and protect. Because a label that fades, peels, or irritates… simply isn’t doing its job.

Is your next collection in need of technical labelling solutions? Looking for sustainable materials without compromising on performance? We’re here to help you find the perfect label for every garment.