In today’s global market, where counterfeiting poses a constant threat, safeguarding the authenticity of garments is more crucial than ever. For major fashion brands and textile manufacturers, every detail matters — yes, even the labels.

At Indet, we’ve spent years designing and printing labels that don’t just inform, but also protect. Today, we’d like to introduce you to a quiet yet highly effective ally: microprinting.

What is microprinting and how does it work?

Microprinting is a technique that involves printing text, numbers, or patterns at an extremely small scale—so tiny that they’re nearly invisible to the naked eye and can only be seen with a magnifying glass or specialised equipment. This technology has long been used in official documents and banknotes to make counterfeiting more difficult, and it’s now gaining ground in the textile industry.

Microprinting works because replicating it requires highly precise and specialised printing equipment. A counterfeiter might get away with copying a label that lacks microprinting, but when they attempt to reproduce one that includes it, the result is likely to be blurry, illegible, or inconsistent with the original—making it much easier to spot a fake.

Practical applications of microprinting on clothing labels

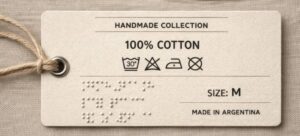

At Indet, we design labels where microprinting is integrated in an elegant and subtle way—without compromising the design or the consumer experience. Some common applications include:

- Microtext along the bottom or side edge: A line of text so small it appears decorative at first glance, but actually contains unique information or hidden codes.

- Inside the logo or brand symbol: Microtext embedded within the graphic design itself, adding a hidden layer of authenticity.

- In a concealed area or on the reverse side of the label: Tiny text placed in a discreet location, visible only to authorised personnel using a magnifying device.

Microprinting can also be combined with special inks, such as invisible inks that reveal themselves under UV light, or thermochromic inks that change colour with temperature—adding an extra layer of security.

Beyond microprinting: other techniques to safeguard your labels

Microprinting is a key element, but for major brands, it’s advisable to combine multiple technologies to make counterfeiting even more difficult. Some of the most effective solutions include:

1. QR codes and unique personalised codes

Each label can include a QR code or a unique alphanumeric code that is non-transferable. When scanned, it gives consumers or distributors access to a platform that verifies the product’s authenticity and provides additional information such as the manufacturing date, batch number, or original point of sale. Advanced systems can also detect suspicious scans or unusual locations, alerting brands to potential counterfeiting or fraudulent reselling.

2. RFID and NFC technology

RFID (Radio Frequency Identification) and NFC (Near Field Communication) chips are becoming increasingly accessible and can be embedded directly into fabric or swing tags. These enable:

- Fast, contactless identification

- End-to-end logistical tracking from factory to store

- Instant consumer verification via compatible smartphones

These technologies serve not only as anti-counterfeiting measures, but also as tools for inventory management and quality control.

3. Security threads and holograms

Just like those used in official documents or banknotes, metallic or coloured security threads can be woven into textile or cardboard labels. Custom holograms—with three-dimensional imagery and optical effects—are also highly resistant to reproduction and add a strong layer of visual protection.

4. Speciality inks

Inks that only appear under UV light, thermochromic inks that change colour with temperature, or inks that react to friction or moisture add yet another layer of security—without altering the visible design of the label.

When to use microprinting and when to combine it with other security technologies

Microprinting is a highly effective technique and, in many cases, sufficient to provide a strong deterrent against counterfeiting. However, the decision to use it alone or alongside other security technologies depends on several key factors:

1. When to use microprinting on its own

Microprinting is ideal when:

- You want discreet and cost-effective protection: As it doesn’t require special materials or additional equipment beyond high-precision printers, microprinting offers an accessible solution that can be integrated into labels without significantly increasing production costs.

- You aim to preserve a clean, elegant design: Microprinting can be incorporated almost invisibly, maintaining the label’s aesthetic without disrupting the consumer experience.

- The risk of counterfeiting is moderate or controlled: For mid-range collections or markets where counterfeiting is less prevalent, microprinting may be enough to deter most counterfeiters.

- You need a first layer of authenticity: It provides a subtle yet verifiable marker of authenticity—hidden, but easy to check using simple tools like a magnifying glass or a mobile app.

2. When to combine microprinting with other security technologies

For major brands, premium collections, or products at high risk of counterfeiting, microprinting should be seen as one component of a broader security system. Combining it with other techniques creates multiple layers of protection, making counterfeiting virtually impossible. This approach is recommended when:

- The brand has high market value and is a frequent target for counterfeiters: Luxury, sports, or iconic brands are often in the crosshairs of sophisticated counterfeiters who may attempt to replicate even microprinting using advanced equipment.

- The product requires advanced traceability: Adding QR codes or RFID alongside microprinting enables both verification of authenticity and detailed tracking of the garment throughout the entire supply chain.

- You want to offer visible reassurance to consumers: Technologies such as holograms or special inks can be made visible to end users, reinforcing the perception of security, exclusivity, and brand integrity.

- A comprehensive defence against multiple types of fraud is needed: From basic copying to illegal reselling or tampering with original products, layered security helps mitigate a wide range of threats.

- Fast verification at retail or distribution points is required: Technologies like RFID or NFC allow for rapid, contactless verification in just seconds—ideal for shops, warehouses, and logistics hubs.

Today’s consumers expect not only quality in a garment but also assurance of authenticity and transparency. A well-designed label—combining visible and invisible security elements—builds trust, protects brand value, and enhances the overall customer experience.

For brands, the label becomes an “invisible signature”—a discreet yet powerful marker that certifies the product’s legitimacy and ensures full traceability. In the event of a claim or doubt, secure labelling allows for quick identification of batches and verification of their origin.

Design, sustainability, and security: A possible balance

At Indet, we’re fully aware that the textile industry is undergoing a vital transition towards sustainability. That’s why we design labels that seamlessly integrate security technologies without compromising on eco-friendly, recycled, or certified materials.

Microprinting, for instance, doesn’t require additional ink or special substrates, making it fully compatible with labels made from organic or recycled fabrics. The same goes for invisible inks and certain types of holograms. In this way, protection against counterfeiting can go hand in hand with environmental responsibility.

In summary, the fight against counterfeiting is a complex challenge that demands innovation and meticulous attention to detail. Far from being just a simple accessory, a garment’s label has become a strategic tool for safeguarding authenticity, strengthening consumer trust, and protecting brand revenue.

Because in fashion, authenticity is printed too.