Have you ever considered how the choice of label can influence the perception of your garments? Beyond being a functional element, labels serve as an extension of your brand’s identity. Factors like image, comfort, durability, and even sustainability play a key role when deciding between thermal labels and sewn labels.

Choosing the right label isn’t always easy. What impact will it have on the customer experience? How does it affect production costs or the final design? At Indet, we understand that making these decisions can be challenging, which is why we’re here to help you weigh the pros and cons of these two label options.

What are thermal and sewn labels?

Before diving into the advantages and disadvantages, it’s essential to understand what each type of label entails and the specifics of their usage. Thermal and sewn labels not only serve different functions but also reflect strategic decisions in terms of aesthetics, comfort, and functionality.

Thermal labels: These labels are printed directly onto the fabric using heat and thermal transfer techniques. They are commonly found in garments where comfort is paramount, such as underwear, sportswear, or children’s clothing. This type of label is practical as it eliminates the need for an additional piece on the garment, adding lightness and simplicity to the design. However, it’s vital to ensure the application process is compatible with the fabric to avoid premature wear.

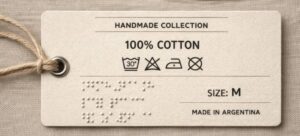

Sewn labels: These are pieces of material (such as cotton, polyester, or satin) that are attached to the garment by stitching. Sewn labels are more traditional and provide a tactile feel that can enhance the perception of product quality. They often contain detailed information and can include logos or designs that add a distinctive touch to the garment.

Advantages of thermal labels

Thermal labels stand out for their practical and functional approach. They are designed to provide comfort to the end user and streamline large-scale production. If you’re looking to simplify processes and enhance the customer experience, thermal labels may be the ideal solution.

- User comfort: Without seams or edges that might irritate the skin, thermal labels are perfect for garments that come into direct contact with the body. This makes them particularly popular in sportswear, underwear, or children’s clothing, where user experience is crucial.

- Minimalist appearance: Thermal labels blend seamlessly into the garment’s design without visible elements that might disrupt its aesthetic. This is an advantage for brands seeking a clean, modern style.

- Easy customisation: Thermal printing technology allows for quick changes to designs, such as including different languages or adapting information to meet international market requirements. This is a significant advantage for global brands or limited-edition collections.

- Cost savings at scale: For large-scale production, thermal labels are typically more economical, as they eliminate additional cutting and sewing processes, streamlining production.

Disadvantages of thermal labels

Despite their benefits, thermal labels aren’t a perfect solution for every scenario. There are technical and aesthetic aspects that may not align with the specific needs of some brands. Assessing these drawbacks will help you avoid long-term issues.

- Limited durability: While thermal labels are comfortable, they can wear out over time due to frequent washing, high temperatures, or friction. This can be a concern for garments that see heavy use or require high durability.

- Fabric compatibility: Not all materials are suitable for thermal labels. For instance, highly textured fabrics, delicate textiles, or water-repellent finishes can hinder clear and long-lasting printing.

- Design limitations: Although customisable, thermal labels offer fewer aesthetic options in terms of textures or sophisticated finishes, which could limit their appeal for high-end garments.

Advantages of sewn labels

If your goal is to convey quality, durability, and a premium touch, sewn labels are a safe bet. This type of label not only reinforces brand identity but also offers a wide range of possibilities to make garments stand out visually.

- Long-term durability: Sewn labels are designed to stand the test of time, withstanding frequent washing and demanding usage conditions. This makes them ideal for workwear, uniforms, and high-end clothing.

- Design versatility: Sewn labels offer endless possibilities in terms of materials, colours, shapes, and finishes. They can include sophisticated details like embroidery, embossing, or special weaves that enhance brand identity and add a premium touch.

- Brand identity reinforcement: A well-designed sewn label can become a distinctive and exclusive element of a brand, instantly recognisable and associated with quality and luxury.

- Suitable for any fabric: Unlike thermal labels, sewn labels are compatible with all types of materials, from delicate cottons to heavier fabrics.

Disadvantages of sewn labels

While sewn labels offer unmatched appearance and durability, they also present challenges that may affect certain types of garments or production processes. It’s important to determine whether these limitations align with your brand’s objectives.

- Reduced comfort: Although many sewn labels are made with soft materials, the stitching can be uncomfortable for some users, especially in underwear or tight-fitting garments. This is a key consideration for garments intended for prolonged use.

- Higher production costs: The manufacturing process for sewn labels is more complex and labour-intensive, which increases costs. This can be a challenge for brands aiming to optimise their budget.

- Impact on aesthetics: In minimalist or modern garments, a visible label may disrupt the desired design. Additionally, balancing functionality with appearance can be difficult.

- Longer application time: Attaching sewn labels requires a slower process, which could delay production compared to thermal labels.

Criteria for choosing between thermal and sewn labels

Making the right choice involves carefully assessing your product’s needs and the message you want to convey as a brand. Are you seeking comfort and simplicity, or do you prefer to stand out with a premium aesthetic? These criteria will help you decide:

- Type of garment: For sportswear, underwear, or children’s clothing, where comfort is a priority, thermal labels are the best option. On the other hand, for luxury garments or exclusive designs, sewn labels provide the desired aesthetic and functional value.

- Desired durability: Garments intended for intensive use or frequent washing, such as uniforms, workwear, or outdoor clothing, require sewn labels for greater resistance.

- Budget: While thermal labels are often more economical, investing in sewn labels may be justified by the perceived quality they bring.

- Brand identity: Sewn labels are ideal for brands seeking to convey luxury and exclusivity, whereas thermal labels align with a functional, modern approach.

- Environmental impact: Sustainability also plays an important role. Some sewn label materials can be recyclable or biodegradable, while thermal labels, though practical, require industrial processes that may have a higher environmental impact.

In summary, the choice will depend on the specific needs of each project. At Indet, we understand the importance of selecting the right solution and offer personalised advice to help you decide which type of label best suits your collection.