Elegir entre etiquetas impresas o tejidas es una decisión crucial para cualquier empresa fabricante de ropa. Aunque pueda parecer un aspecto secundario, esta elección influye directamente en la percepción del producto, la durabilidad del etiquetado y la comodidad del cliente. Muchas marcas se preguntan: ¿Es mejor una etiqueta impresa, que ofrece ligereza y versatilidad de diseño, o una etiqueta tejida, que aporta durabilidad y un acabado más premium?

Tomar la decisión incorrecta puede afectar la imagen de la marca, la experiencia del consumidor e incluso los costes de producción. Entonces, ¿cuál es la mejor opción? A continuación, analizamos en profundidad los pros y contras de cada tipo de etiqueta para ayudarte a tomar la mejor decisión para tu marca.

Printed labels

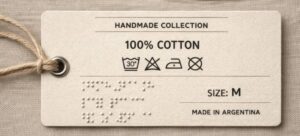

Printed labels are those in which information and design are applied using ink on a textile or synthetic material.

Advantages of printed labels

- Design versatility – They allow for intricate details, gradients, and a wide range of colours with ease, making them ideal for brands aiming to convey a vibrant and creative visual identity. Additionally, QR codes, detailed washing instructions, or certifications can be printed without losing clarity.

- Lower production costs – Generally more cost-effective than woven labels, as the printing process is simpler and faster. This makes them an excellent option for businesses handling large production volumes while seeking to reduce costs without compromising customisation.

- Soft and lightweight feel – Being printed on materials like satin or cotton, they provide a more pleasant sensation for the wearer. This is crucial for garments that come into direct contact with the skin, such as underwear or T-shirts.

- Fast production – Printing is a quicker process than weaving, offering greater flexibility for changes and urgent orders. This is especially beneficial for brands operating with short production cycles or requiring frequent label updates.

- Ideal for Sportswear and underwear – Due to their lightweight and flexible nature, they do not cause discomfort on the skin and allow the garment to maintain its comfort even after multiple washes.

Disadvantages of printed labels

- Limited durability – With repeated washing and wear, the print can fade or crack, reducing the readability of the information. This wear is more noticeable in garments that require rigorous maintenance, such as sportswear or work uniforms.

- Lower perceived quality – Some high-end brands tend to avoid printed labels, as they can convey a sense of lower exclusivity and durability, potentially affecting the product’s image.

- Less durable materials – While high-quality options exist, many materials used for printed labels tend to wear out faster compared to woven labels, making them less suitable for products designed for long-term use.

Woven labels

Woven labels are made by interlacing threads of different colours to create the brand’s design and information.

Advantages of woven labels

- High durability – Since they are woven, the information does not fade with washing or prolonged use. This makes them ideal for garments that must withstand multiple wash cycles without losing label clarity, such as jeans, coats, or workwear.

- Higher perceived quality – Highly valued in premium products and by brands aiming to convey exclusivity and attention to detail. The texture and elegant finish of a woven label can enhance brand identity and differentiate the product in the market.

- Wide variety of textures and finishes – They can be produced in different thicknesses and qualities, such as taffeta, satin, or damask, allowing brands to tailor the look and feel to their image while providing a pleasant sensory experience for consumers.

- Greater resistance to extreme conditions – Ideal for workwear, denim, or garments requiring durable labelling. They do not deteriorate from continuous friction or exposure to harsh conditions, making them the preferred choice for outdoor or industrial clothing.

- More professional and luxurious appearance – They are associated with well-crafted design and can become a brand’s signature element, helping to build customer loyalty by conveying a higher-quality image.

Disadvantages of woven labels

- Less design flexibility – Although they can achieve great detail, they do not allow for gradients or certain advanced printing effects. This can be a limitation for brands wanting to include highly detailed graphics or a large amount of information on the label.

- Higher cost – Their production is more expensive compared to printed labels due to the complexity of the weaving process and the need for high-quality threads. This can be challenging for brands with tight budgets or large-scale production needs.

- Greater rigidity – Depending on the type of weave, they may be less comfortable when in direct contact with the skin. Some woven labels can feel rough or bulky, potentially causing discomfort in everyday clothing or sportswear.

- Longer production time – The manufacturing process for woven labels takes longer than printing, which can be a drawback for urgent orders or businesses operating with fast production cycles.

Which one should you choose for your brand?

The choice between printed and woven labels depends on several factors, such as the type of garment, budget, and the brand image you want to project. For fast fashion brands or sportswear, printed labels may be the best option due to their lower cost and comfort. On the other hand, if your goal is to convey luxury, exclusivity, and durability, woven labels are the more suitable alternative.

For a balance between quality and cost, some brands use woven labels for outerwear and printed labels for garments that come into direct contact with the skin. This approach ensures a mix of aesthetics, comfort, and cost-effectiveness.

A well-designed label not only provides essential information but also reinforces brand identity and influences the consumer’s perception of the garment. Ultimately, it’s a small detail that makes a big difference in the customer experience.

> > Check out our article on Thermal labels vs. sewn labels: Pros and cons.